FOR A BOLD & BETTER FUTURE.

As a globally engaged business, we have a special responsibility. We know that our activities have an impact on the planet. It is our aim to keep this as low as possible to ensure a bold and better future for the current and future generations. Our activities are entirely in the spirit of ´FOR A BOLD & BETTER FUTURE`. To live up to our responsibility, we take a strategic approach and base our decisions on a firm foundation of our sustainability activities.

OUR SUSTAINABILITY STRATEGY AT A GLANCE

FOR A PLANET FREE OF WASTE AND POLLUTION

Our sustainability strategy is focused on running our business without waste and pollution and therefore to protect our planet. Founded on a strong environmental, social and governance (ESG) core in the areas of PRODUCT, PEOPLE and PLANET, we do our best to initiate continuous change towards more sustainability within the industry.

Learn more about our five strategic key pillars as well as our ESG-Core and how we strive to create positive change in these areas in our Sustainability Booklet.

DEEP-DIVE INTO OUR STRATEGIC KEY PILLARS

-

1. INCREASE CIRCULARITY

Our commitment: 80% circular apparel products by 2030*

- Our CIRCULAR styles fulfil all three criteria. They are made:

- with renewable or recycled raw materials (excl. trimmings)

- to be made again: our products are recyclable (excl. trimmings)

- to last longer: our products are designed for longevity

- We offer ‘circular’ services such as our resale collaboration with Sellpy to sell and buy pre-loved pieces. And we have also gained valuable experiences with repair services in select cities in Germany.

*In fabrics and linings

- Our CIRCULAR styles fulfil all three criteria. They are made:

-

2. DRIVE DIGITIZATION & DATA ANALYTICS

Our commitment: >90% of products will be developed digitally by 2025

- Digital product creation entails the transformation of physical product development steps into digital processes: from product design and digital prototyping to interactive product presentations based on 3D simulation and animation.

- By using 3D simulations to create "digital prototypes", we have already been able to significantly cut down physical samples during product development. Here we still see great potential for further reduction.

- With data analytics, we aim to generate data-driven insights by leveraging our data end-to-end. By making reliable forecasts and recognizing trends, we will be able to optimize our purchasing and ultimately, avoid waste and reduce our CO2-emissions thanks to customized production and transport. Our Digital Campus plays a decisive role here.

-

3. LEVERAGE NATURE POSITIVE MATERIALS

Our commitment: 100% natural materials from regenerative agriculture or closed-loop recycling by 2030*

- By 2030, we aim to source all our natural materials (such as cotton and wool) through regenerative agriculture or closed-loop recycling.

- Regenerative agriculture is a nature-positive approach to cultivating raw materials that contributes to environmental restoration by promoting soil health, carbon sequestration and biodiversity. The aim is to protect our soil, so the foundation of life remains healthy.

- In closed-loop recycling, we only use recycled pre- or post-consumer textile waste.

*In fabrics and linings

-

4. FIGHT MICROPLASTICS

Our commitment: 0% polyester & polyamide by 2030

- By 2030, we aim to phase out polyester and polyamide in all fabrics and linings, including blends, in our products.

- It is one more important step to protect our planet and biodiversity and ensure no microplastics are being washed out of clothes.

- We are always on the lookout for a true alternative to polyester and polyamide fibers. With HeiQ AeoniQ we have found an answer. It is an innovative cellulosic yarn that can serve as an alternative to traditional synthetic fibers like polyester or polyamide.

- In 2023, we released the first HeiQ AeoniQ styles in the market, which by now include polo shirts, a sneaker and outerwear styles.

- Collaborations like these are critical to achieving our goal.

*in fabrics and linings, assumption is availability of more sustainable alternatives

-

5. PUSH ZERO EMISSIONS

Our commitment: -50% CO2 emissions by 2030 (compared to 2019)

The CO2 emissions we want to reduce to Net Zero by 2050 include all emissions along our value chain (scope 1-3): from own energy consumption, transportation and manufacturing to the cultivation of raw materials.

- Regenerative agriculture has the potential to significantly reduce the CO2 emissions produced during the procurement of our raw materials like cotton.

- In the supply chain, we focus on saving energy at our suppliers’ end and the reduction of airfreight in transportation.

- In our own buildings, we attach great importance to implementing energy efficiency measures, generating renewable electricity from our own photovoltaic systems and procuring electricity from renewable energy sources.

A solid foundation

As an organization, we are involved in many initiatives protecting our planet by promoting resource efficient cultivation or processing methods and for more social cohesion by protecting human rights in our supply chain. Our sustainability strategy ensures that all our activities are in alignment with and jointly contribute to one main goal: to delight our customers with responsibly manufactured products.

Our strategy incorporates the latest scientific findings and the results of our own analyses, as well as information obtained through exchange and collaboration with political institutions, civil society, and investors. In all of this, we attach great importance to a targeted and focused approach in order to create long-term value for our society as a whole.

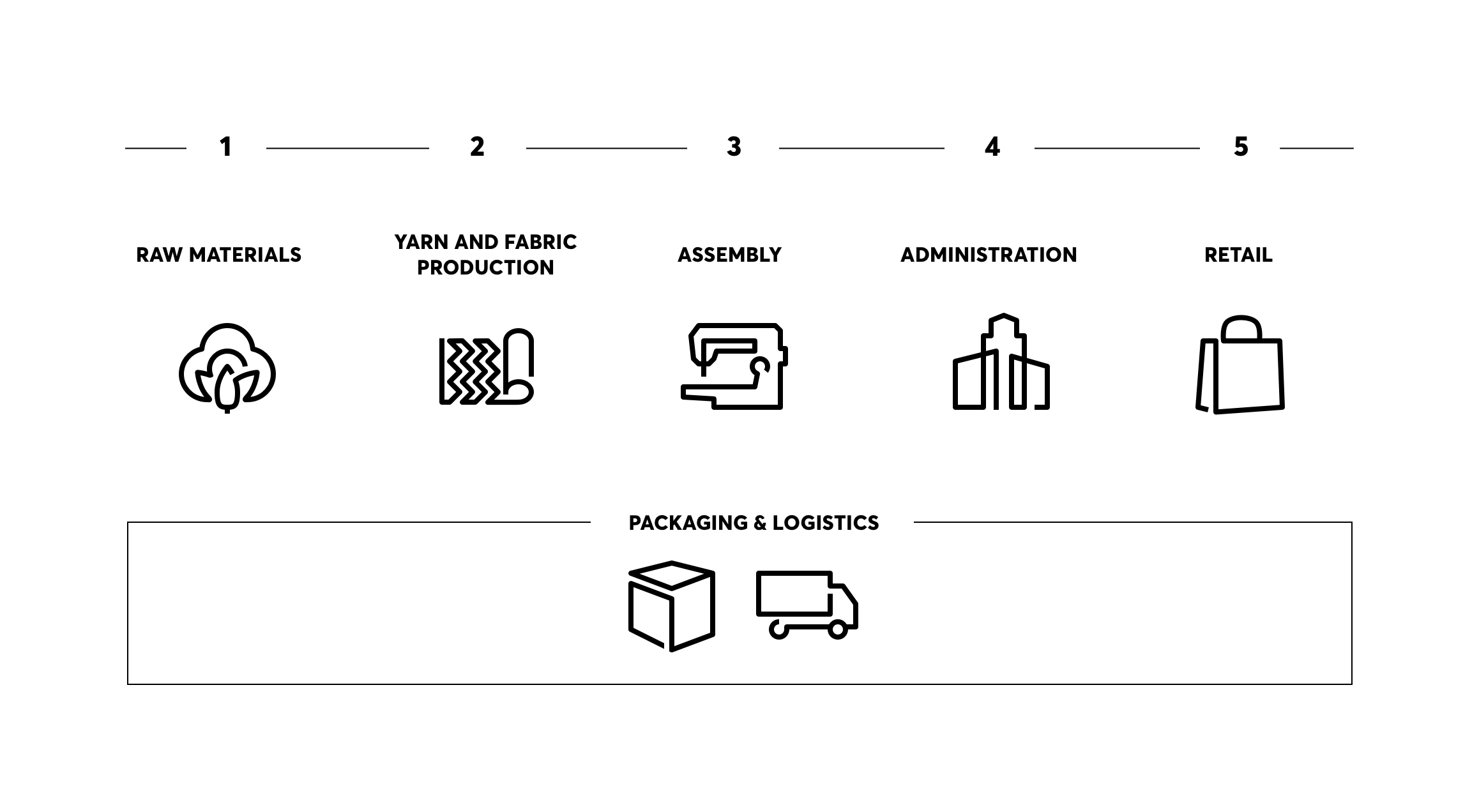

WE MANAGE SUSTAINABILITY ALONG THE ENTIRE VALUE CHAIN

Raw materials purchased globally; collaborating with partners, suppliers and customers all over the world; materials and products that go back and forth between them all: the HUGO BOSS value chain is complex. We are working on every link in the chain to make it more sustainable. Our materiality analysis, the natural capital assessment and continuous dialog with various stakeholders help us to plan and implement our activities effectively.

-

Raw materials

The basis of all our products are the raw materials, such as cotton, wool, or leather. The value chain, therefore, begins with the procurement of materials. We search for better materials like cotton from regenerative agriculture, ensure their production process is resource-efficient by saving resources like energy and water, and that we are in compliance with other important aspects, such as animal welfare. The circular economy (circularity) is taken into consideration right from the start.

-

Yarn and fabric production

During yarn and fabric production, raw materials are processed into textiles, from which the finished products are later created. Measures for more sustainability in this area include strict management of chemicals, economization on water and waste in production, as well as reduction in energy consumption.

-

Manufacturing

The designs in the collections take shape in the garment production facility. Textiles are fitted and sewn, and prototypes and series products are manufactured. We strive to minimize waste during the cutting and sewing process, so that we deliver high-quality products, reduce the amount of rejects, and provide high standards of workplace health and safety. Our relationships with suppliers and service providers are based on a respect for human rights and the observance of high social standards.

-

Administration

To ensure that all processes run smoothly, the administration controls and monitors all the steps, from raw material procurement to the shipment of products.

-

Sales

Finally, the sale of finished products takes place in the company's own retail stores or through sales partners.

-

Packaging and logistics

Different types of packaging are used along our entire value chain, and different modes of transport are used as part of the logistics process. We design these processes in a more sustainable manner, by optimizing the transport routes and using modern technology and more responsible raw materials, defined by strict standards.